How to Make Waste Management and Recycling Smarter with AI

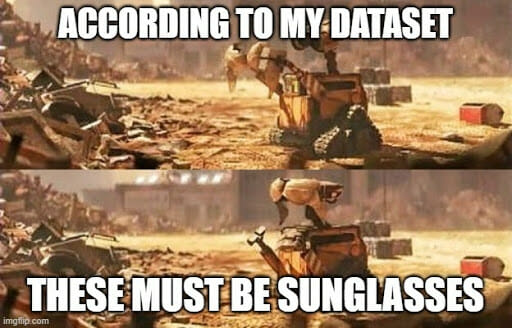

Poor WALL-E. It must have seen too few bras in its long robotic life to properly sort them from other waste.

So… how can we teach it and all the other robots to better separate trash? And how can we improve the entire waste and recycling industry in general?

The short answer to this question is “AI and machine learning“. The long one … well, you can find it in today’s article!

AI in the waste and recycling industry

Waste management is one of the many challenges that hopefully humanity will be able to tackle effectively thanks to the contribution of artificial intelligence and machine learning.

The problem we face is quite serious: according to the World Bank, in 2016 the world generated 2 billion tons of municipal solid waste, and this amount is expected to increase by 2050 to 3.4 billion tons.

At the same time, recycling rates aren’t particularly comforting. Just think of the measly 8.5% recycled plastic in the United States in 2018.

“According to the World Bank, in 2016 the world generated 2 billion tons of municipal solid waste, and this amount is expected to increase by 2050 to 3.4 billion tons.”

AI comes to our aid

Nowadays, major recycling facilities implement sophisticated sensors to a greater or lesser extent to sort different types of garbage flowing through the intricate webs of conveyor belts.

AI-powered systems are able to scan waste with computer vision and guide robotic arms, which nimbly rummage through the piles of waste in search of precious materials to be recycled.

As quickly and easily as retirees on vacation in tourist villages rummaging through the buffets. Just in a much neater way.

Robots do what consumers don’t

Sorting is an essential prerequisite of the recycling process, especially considering that 80% of recycling services in America use a single sorting system. This means that all the material ends up in the same bin, and once it arrives at the recycling facility it must be separated.

Yes, cardboard and plastic cannot be recycled in the same way. Welcome, Captain Obvious!

Fortunately, artificial intelligence technologies make a great contribution to correctly classifying and sorting different types of waste in recycling plants.

How do robotic sorters work?

How robots work is pretty simple. Basically, they assist their “human colleagues” by working up to twice as fast thanks to the use of cameras and computer systems trained to recognize specific objects.

Moving their mechanical arms equipped with numerous sensors, they grab each recyclable object from the conveyor belt and place it in the appropriate containers.

AI-powered sensors have proven far superior to traditional optical options, as they are able to identify not only the type of material but also additional characteristics such as contamination from other chemicals.

This is a fundamental aspect of the resale phases of recycled materials, as we will see later (no spoilers!).

The role of machine learning

Wow, everything sounds pretty cool! Just one question… how can machines detect not only easily recognizable objects but a messy mix of dirty, crumpled, broken items, even contaminated by external agents?

The trick can be found in machine learning, a branch of artificial intelligence that provides systems with the ability to automatically learn from data and improve with experience without being explicitly programmed.

And how do we apply this approach to waste management?

Basically, we have to train our computers to recognize everything that passes on the conveyor belt by showing them thousands of images … of garbage. Not exactly as pleasant as swiping on Tinder, right?

The importance of data and training sets

By analyzing large sets of training images, machine learning-based systems learn to recognize different shapes, textures, patterns, and colors and consequently identify the different types of waste to sort.

And when I say “large training set”, I mean LARGE.

That’s because distinguishing a stained pizza box from a crumpled can, each of which is positioned and oriented on the conveyor in different ways, requires the creation of a large representative data set.

The coolest thing about this learning process is that it’s potentially never-ending. The more a machine scans new “data” (junk, trash, rubbish, waste, garbage, you understood, right?) the more it improves its future performances.

AI gives robots the gift of touch

The waste analysis is not limited to a visual examination. A group of researchers from MIT’s Distributed Robotics Lab is developing sensors for these robots that can greatly increase their tactile sensitivity.

This way, machines will integrate computer vision with an additional sense to determine the nature of an object and further reduce the risk of misjudgments.

If you cannot recognize it… touch it!

Other applications of AI in the waste industry

The role of artificial intelligence in waste management is not limited to the separation of materials to be recycled.

Indeed, we can expect the general digitalization of the sector to improve the purely logistical aspects as well. What about a fully automated waste transport, coordinated by AI and optimized to reduce travel times and therefore emissions?

A similar solution has already been implemented, for example, by some construction companies to organize waste disposal in a few minutes simply with a touch on a smartphone.

Helping consumers with AI

Another potential field of application concerns assistance to consumers. Imagine AI-powered bots that help users sort household waste into separate collection bins.

A similar system is being tested in some Chinese megacities, including Shanghai. Citizens can be guided by specific apps to determine if their Peking duck leftovers should be placed in the organic waste bin or somewhere else.

I honestly never figured out which bin to put the bones in (every website says something different).

If anyone knows, write it down in the comments, please. Otherwise, I’ll have to download another Chinese app.

Why we need AI more than ever

Traditional technologies (such as infrared-guide sorters and mechanical systems for waste disposal) were certainly a valuable tool, but still not smart enough to get the job done alone.

Why? Let me explain…

After sorting, processing, and packaging the recyclable materials, MRFs (material recycling facilities) can sell what they got to brokers or manufacturing facilities.

The process can seem pretty straightforward, but believe me, it’s not!

Brokers are difficult clients

Buyers are very selective and accept the materials according to specific requirements. For example, they could refuse materials that risk being food-contaminated.

This means, for example, that the MRF won’t be able to sell a plastic bottle and a plastic package of delicious prosciutto to the same broker, even if these materials are indistinguishable from the electronic eyes of an infrared camera.

That’s why we still need teams of human workers to watch over the action of the machines, preventing pizza boxes from ending up with used ketchup bottles.

NO KETCHUP WITH PIZZA. NEVER. EVEN IN DEATH.

Working in recycling facilities is a hard job

So, we service the machines with human operators and everything is solved. Right? Hey, not so fast!

Another issue to consider is the safety of workers in the field of waste recycling, who are much more at risk of injury than the average, according to research from the University of Illinois.

Beyond that, we’re talking about a particularly hard, repetitive, and boring, albeit well-paid, job, carried out in a working environment that is certainly not healthy.

That’s why employee turnover in modern recycling centers is so high and companies struggle to find new workers.

Of course, even the fact that every mother points out waste workers as “what you will become if you don’t study” does not improve the reputation of these jobs…

“Another issue to consider is the safety of workers in the field of waste recycling, who are much more at risk of injury than the average.”

Let others handle your garbage (?)

In the past years, the problems described above have been partially compensated by delegating the assignment to foreign countries, which dealt with both recycling and landfill storage.

And by “foreign countries” I essentially mean developing countries ready to pocket money to do the (literally) dirty work.

But like a hydra that grows many heads after cutting off one, the solution has also been the source of further problems.

First, recycling techniques were often not up to Western standards and, as a result, raw materials received back from foreign companies were often contaminated or of poor quality.

Secondly, such a choice has made America and Europe dependent on external agents, primarily China. That worked until China said: “not anymore” in 2018.

China doesn’t want bad quality waste

For many years, China has been committed to recycling much of its waste from the United States, for example by turning plastics into pellets.

The problem was that more and more garbage was sent without being previously and properly sorted. It is estimated that a quarter of the material received was not recyclable and therefore had to be buried or incinerated.

Consequently, the Chinese government determined that only cargoes containing up to half a percent of contaminated materials (such as food packages) would be accepted.

From great crises come great technologies

The challenges associated with waste disposal and the optimization of recycling operations have led companies to seek technologically advanced solutions based on AI and machine learning.

Great steps have already been taken in this direction. For example, robots have become much cheaper and more efficient at sorting waste on conveyor belts, going from around 40 to over 80 items per minute in just two years.

This means that over the years machines will be able to take on more and more tasks and lighten the human workload.

However, this does not mean that artificial intelligence can reduce the amount of waste that goes to landfills or lead people to a more sustainable lifestyle.

For that, we need education, a long-term vision, and a little bit of HUMAN intelligence.