AI in the Oil Industry: Finding and Extracting Petroleum with Algorithms

Artificial intelligence and machine learning technologies offer a wide range of benefits to the oil industry, from research of new sources to extraction and distribution.

Wanna know something more about these advantages?

Be ready, cause the list is pretty long!

Oil localization and extraction: the role of AI

For a person like me who can’t even find his glasses while wearing them, the art of spotting oil fields has always been incredibly fascinating.

This resource discovery process (and subsequent extraction tasks) requires massive investments and represents a high-risk bet.

You know… drilling in the wrong position or mishandling malfunctions means losing millions of dollars.

That’s why oil companies count on a wide array of modern AI-based tools to make localization and extraction processes easier, safer, and cheaper.

AI’s fields of application in the oil industry

Artificial intelligence in the oil industry performs many tasks. These are probably the main ones:

- Predicting the location of new resources

- Optimizing extraction and maintenance processes

- Reducing environmental and personnel risks

Wow, that’s a lot of stuff! Let’s drill delve into it a little bit more.

Petroleum in the modern world

Despite all the disputes on environmental problems, oil is essential for the maintenance of industrial civilization as we know it. It represents a considerable percentage of world energy consumption, ranging from around 30% for Europe to over 50% for the Middle East.

Petroleum is also the basic material for producing many chemicals, including drugs and plastics.

Considering this data, it’s no wonder that the revenue generated by the top 9 oil and energy companies alone amounts to $ 3 trillion, according to Fortune Global 500 estimates for 2019.

Petroleum represents a considerable percentage of world energy consumption, ranging from around 30% for Europe to over 50% for the Middle East.

A reasonable solution: using AI

Finding a compromise between our oil addiction and greater attention to environmental and human issues is quite a challenge.

Obviously, the long-term goal would be to switch to purely renewable sources. If you are interested in these topics (or your name is Greta), take a look at our articles on wind and solar energy!

In the meantime, what we can do is minimize the negatives and maximize the positives of the oil industry through the massive implementation of artificial intelligence and its algorithms.

How to do it, in practical terms? Let me start with the main application of AI in this field: detecting petroleum potential areas.

1. Drilling in the right place with AI

As you can imagine, empty digging is REALLY a pain in the a**.

I mean, wasting two minutes to find my pen drive is already a good reason to curse in five different languages. Think about petroleum engineers mistaking a drilling location!

That’s why the oil industry has always invested in scientific research to predict the location of new potential fields better and faster.

The first step to find oil: collecting data

Considering that we still don’t have Superman’s X-ray vision, the only way to determine hydrocarbon potential locations is by studying the soil.

The main trick to limit exploration to relatively small areas (wasting a lot less money and time) is the detection of petroleum traps. A trap is a geological structure that allows the accumulation of hydrocarbons in a reservoir.

These structures always leave some surface and subsurface marks, which can be spotted thanks to the analysis of magnetic anomalies, underground fractures or cracks, seismic activities, lithological data, and so on.

How to get good soil information

The collection of these valuable clues can be done through coring, which offers extremely precise information on the chemical composition of the soil. On the other hand, it is a rather expensive and time-consuming process.

Basically, we can’t dig everywhere. Despite their billionaire revenues, the oil companies’ resources are limited and some areas may simply be inaccessible for field research.

Like the brown cubes in Mr. Driller videogame.

For this reason, we can combine “on the field” analyses of the petrophysical parameters with other less precise but cheaper and faster tools, such as gamma-ray and resistivity analysis.

Even satellite remote sensing is a great way to catch information regarding structural lineaments, specific features in a landscape due to underlying geological structures.

What if data is a mess?

What to do once we get all this sweet data? Well, here come the troubles…

Unfortunately, the typical geologic data is well known for its complexity, sparseness, and impreciseness.

As we’ve mentioned before, information about soil comes from a multitude of different sources and tools, which should be combined together in some sort of realistic and all-encompassing model.

The previous approaches based on geostatistics techniques were surely nice and welcome help for oil specialists but struggled to manage all this mess.

Artificial intelligence comes to our aid

The progress of AI technologies, mainly driven by machine learning development, offered petroleum engineers new solutions to solve the problem of oil reserve detection.

If you think that “machine learning” is a Klingon or Elvish word, maybe it’s time to check this guide.

Are you too lazy busy?

Summing up, machine learning (ML) is a recent branch of AI, specialized in creating computer algorithms that can autonomously improve their performance through experience.

This “experience” is essentially the analysis and processing of huge amounts of data.

ML algorithms are able to recognize specific patterns in the datasets they are trained with, build mathematical models regarding these relations, and use the models to make decisions or predictions.

The great leap forward: deep learning

Another step forward has been taken with the rise of deep learning (DL), an evolution of machine learning that mimics the mechanisms of the human brain to process information by using deep artificial neural networks (ANNs).

DL systems are able to recognize the most abstract and mysterious patterns by peering deeply into the data and processing the information through the numerous layers that make up these networks.

Using ML and DL, we can train computers with data collected during past oil discoveries and analyses. The algorithms combine different kinds of geophysical data and identify key relationships between them, finding logic within all this variability.

Among the most common algorithms for resource discovery, we can mention support vector machines, ascendant hierarchical clustering, self-organizing maps, and multi-resolution graph-based clustering

Once a model is built, our AI-powered system will be able to detect new potentially productive areas with similar patterns regarding the soil composition and geological structures.

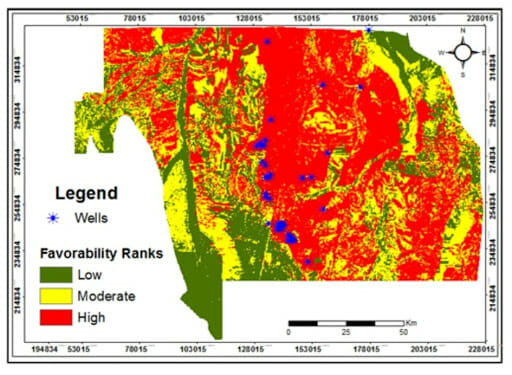

Visualizing data: prospectivity maps

The localization process also involves the creation of prospectivity maps, that leverage and aggregate all the different kinds of data to display the potential likelihood of new oil field locations.

Something like this:

Prospectivity maps can only be deciphered after 25 years of geology studies, or by smoking something stronger than a cigarette… something legal in Amsterdam and Colorado.

Fortunately, I found one with a legend to make your life easier. Thank me later.

2. AI for production and maintenance optimization

All right, let’s move on to the second field of application of AI and ML in the oil industry: the optimization of production and maintenance processes.

Yes, because once you have found the oil, you have to extract it as effectively as possible. After seeing the prospectivity maps, did you think it was just a frustrating treasure hunt?

Once again, the predictive power of algorithms and their incredible ability to handle complex data comes to our rescue!

Drilling correctly with machine learning

Collecting geologic data allows oil companies to predict how formations will react to specific drilling techniques.

In fact, combinations of ML algorithms can be fed with this data, create models of the soil, and offer oil engineers the best path through a rock formation, both in terms of drilling direction and rate of penetration.

ML-powered systems will not focus on single variables but take into account a wide range of factors that could potentially shape the drilling strategy. Among them: seismic vibrations, equipment features, seismic vibrations, soil permeability, and thermal gradients.

Oil extraction automation: the role of APCs

Ok, we found the oil and started drilling. Then? Well, time to talk about APCs…

An oil field usually consists of many oil wells. Each of them requires an Advanced Process Control (APC) system that autonomously handles the choke valve, electrical submersible pump (ESP) speed, and all the other components of the facility.

I said “each of them”, nobody excluded. We don’t want to create emotional trauma in some well.

The APC automatic manipulation is necessary in order to achieve target production while operating the ESP efficiently within its operating possibilities.

How to make APCs better with algorithms?

The core of each APC system is an empirical model of the oil well filled with information about the main well variables, such as temperature, pressure, amps, etcetera.

Developing each model separately is quite a challenging job that can be avoided by treating wells with similar characteristics and patterns in groups and using ML algorithms (especially clustering) to combine all this data.

Such a mechanism was implemented, for instance, by the Saudi Arabian national oil company “Saudi Aramco”, enabling an 80% reduction in the engineering effort to develop the wells models.

What about maintenance?

All this techy stuff sounds really cool. Until it breaks.

The best way to reduce maintenance costs is to predict failures before they occur, using an ML-based predictive maintenance approach. This involves observing the components of an oil well and spotting changes in their operation that could be a sign of future failure.

Basically, algorithms examine the various activities of the oil facility, detecting any sign of shifting from the ideal performance data used to train them.

This data is collected by specific sensors and processed through a wide range of ML-based methodologies. In particular, neural networks (NN), support vector machines (SVM), and decision trees are the most commonly used.

Of course, the same can be done to scan the integrity of pipelines and avoid disastrous oil spills.

3. AI to face environmental and personnel risks

Hey, did I just say “disastrous oil spills”? Yep, that’s quite a big deal.

Oil is normally stored in central repositories and then distributed across pipelines. These distribution systems are prone to material degradation and corrosion, due to different temperatures and environmental conditions.

Failure to manage this problem in advance can result in catastrophic damage that disrupts the entire manufacturing process and causes environmental disasters.

This happened in the Macondo Incident of 2010 when 4.9 million barrels of oil were spilled, and 850 million dollars were spent by the US government for cleaning up the mess.

The ML-based predictive maintenance mentioned earlier is a great way to prevent accidents like this from happening. AI technologies can detect signs of corrosion by analyzing various parameters, forecast the likelihood of corrosion, and send an alert.

AI and ML for personnel safety

All this talk of apocalyptic accidents should have given you an idea of the dangers associated with the oil industry. But that’s not all.

Oil plants operate in truly critical environments. This means that the risk of injury is much higher than in many other industrial environments.

Think of the huge temperature range, exposure to toxic fumes, fires and explosions from oil spills or malfunctions, and deadly monsters born from petroleum (see image below).

How can AI protect oil industry workers?

Artificial intelligence ensures better and faster decision making, which is an essential prerequisite for improving the health and safety conditions of oil plant personnel.

AI-powered systems can collect a wide range of data from sensors and cameras in real-time, subsequently detecting anomalies and potentially dangerous events thanks to our favorite algorithms.

These tools can also be combined with wearable sensors, which continuously monitor worker behavior for any signs of physical distress and send an alert.

Petroleum and algorithms: towards new horizons

The influence of AI in the oil industry is not limited to exploration and production. Energy operators have already begun to rely on ML predictive analytics to improve the distribution process.

Indeed, algorithms can see through economic data to predict demand, allocate resources, and set optimal prices.

Their implementation seems destined to permeate every aspect of the oil sector, even if this industry still lags behind some others when it comes to exploiting artificial intelligence up to its full potential.

Will we even see AI-powered machines wage wars to grab oil resources?

Naaah, that’s business for humans.